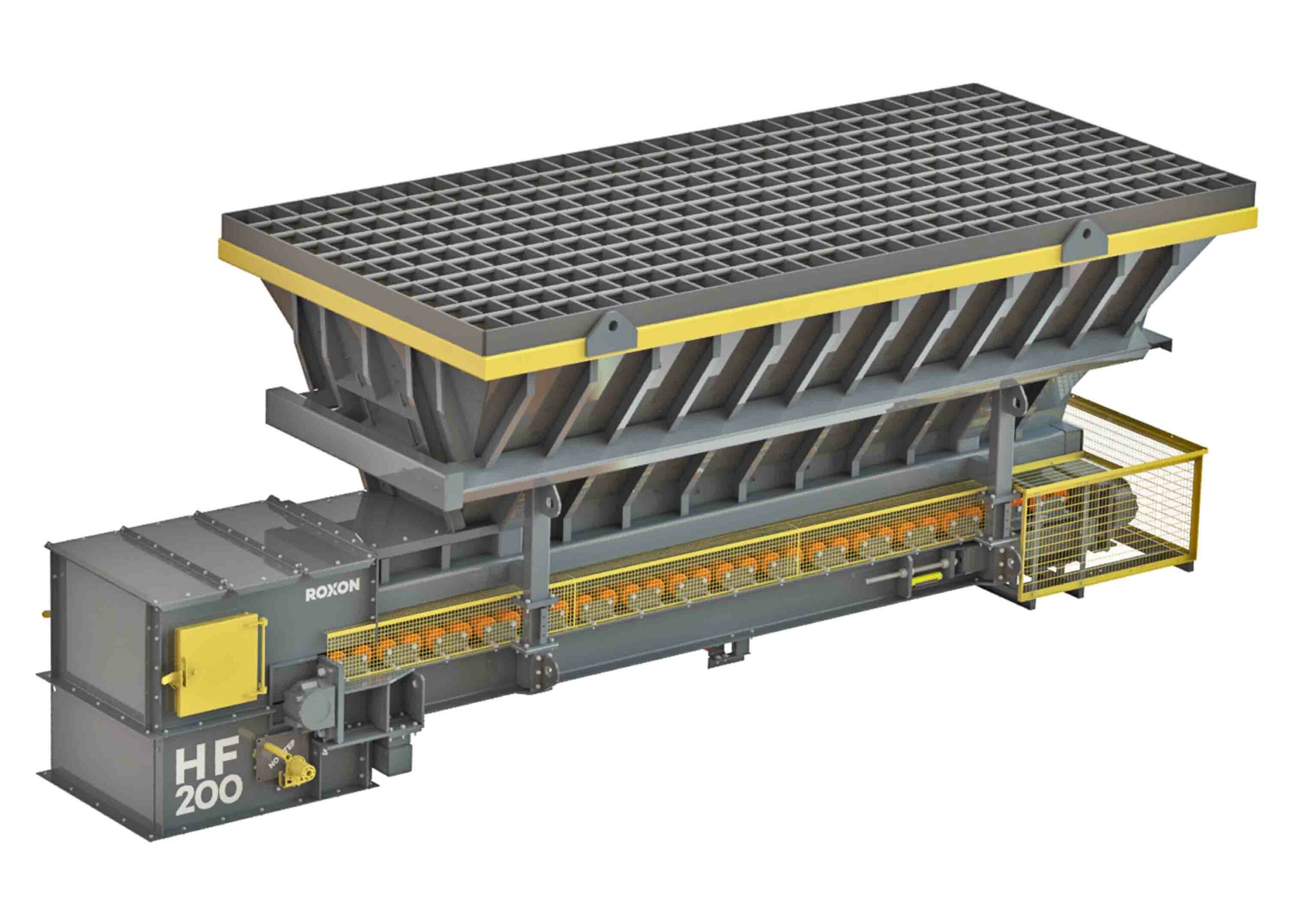

HF200 Belt Feeder

HF200 Belt Feeder is standardized for receiving duties. HF200 Belt Feeder is usually arranged to receive bulk material from trains, trucks and bucket loaders or similar. Typical feed materials include different types of ores, coal, limestone and similar raw materials. Vibration free operation, accurate and steady material flow is ideal for bulk materials with fine grain size.

Proven Design to Meet the Demands

With over 1000 standard and tailor-made belt feeder units delivered, the gained expertise is used to fulfill the application demands. Adjustable material height gate can be used for capacity adjustment. More accurate and wider capacity range can be achieved with an optional frequency converter.

Designed with Safety in Mind

HF200 is supplied with high quality mesh guards protecting against hazards and still enabling visibility for maintenance. Pull cord emergency stop system or push buttons, belt misalignment switches and rotation detector sensor are also provided as standard.

Higher Reliablity

Non-closed machine structure ensures easier maintenance access and visibility. Rollers are lubricated for life and centralized lubrication for drive and tail shaft bearings is available as an option. Standard components are used for easier spare part access.

Key Specifications

| HF200- | 800/5 | 800/7 | 1000/5 | 1000/7 | 1200/5 | 1200/7 | 1400/5 | 1400/7 | |

| Maximum Capacity | m3/h | 500 | 500 | 900 | 900 | 1250 | 1250 | 1800 | 1800 |

| Belt Width | mm | 800 | 800 | 1000 | 1000 | 1200 | 1200 | 1400 | 1400 |

| Feeder C-C Length | m | 5 | 7 | 5 | 7 | 5 | 7 | 5 | 7 |

| Standard Hopper Water Volume | m3 | ~12 | ~18 | ~12 | ~18 | ~12 | ~18 | ~12 | ~18 |

| Outlet Width (Inside Skirtboards) | mm | ~580 | ~580 | ~760 | ~760 | ~900 | ~900 | ~1100 | ~1100 |

| Inlet Lenght x Width | m | 4.7 x 2.8 | 6.7 x 2.8 | 4.5 x 2.8 | 6.5 x 2.8 | 4.3 x 2.8 | 6.3 x 2.8 | 4.1 x 2.8 | 6.1 x 2.8 |

| Belt Speed, Nominal Maximum | m/s | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 |

| Installed Power Range | kW | 3-22 | 3-22 | 3-30 | 3-30 | 4-37 | 4-37 | 5.5-55 | 5.5-55 |

Any questions?

Complete the form or talk to any of our professionals.